These state of the art ultralow temperature freezers operate within a temperature range of between 90 c and 40 c guaranteeing a constant low temperature that can be adjusted to the accuracy of one degree.

Low temperature ceramic binder.

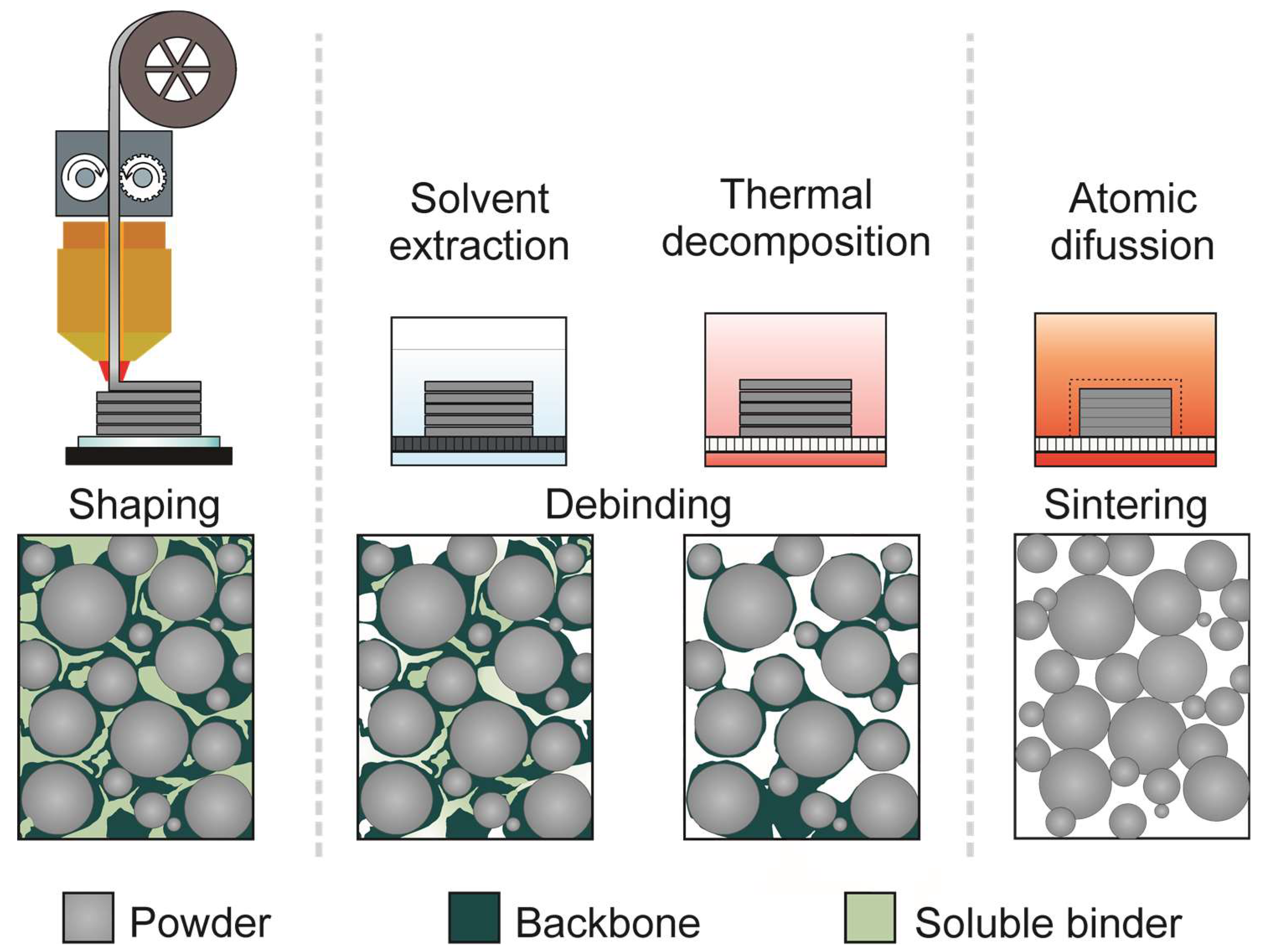

Removal of binders is an important step during high temperature sintering process and under ideal conditions binder removal should be complete before consolidation of ceramic particles has started.

Values but its strength decreased with increase in binder concentration while the reverse occurred for pva and dextrin containing pellets.

Providing maximum security and reliability binder units are suitable for biological chemical and medical samples.

643 1 a basic solution compatible with most ceramic and metal powders.

Fully cures at low temperatures and sets up in thick.

Fully cures at low temperatures and sets up in thick cross sections when properly formulated.

The use of qpac in ultra low temperature co fired ceramics ultcc july 26 2018 read more using qpac polyalkylene carbonate as a solid state electrolyte for flexible solid lithium batteries.

It is a strong surfactant and binding power is connected to its ability to wet particles products having a low molecular weight exhibit low viscosities and they have.

Excellent binder for producing high temperature protective coatings and refractory and chemically resistant adhesives and patching materials.

Qpac can be used as a sealing glass binder in low temperature sealing glass applications in which low temperature glass is used to seal to other glass substrates.

The ceramic parts contain only 2 5 vol binder solids basis which increases the strength of the ceramic systems by at least a factor of 8 while the strength of al2o3 components increases by a.

Usually it is used as a binder for glazes during glazing operations before the screen printer a water solution of polyvinyl alcohol is sprayed on the surface to be decorated.

Ultra low sintering temperature silver molybdenum oxide ag 2 mo 2 o 7 ceramics have been printed using direct ink writing a material extrusion additive manufacturing process for the first time an optimum densification conditions of 460 c 2 h was determined resulting in relative permittivity ε r 13 45 dielectric loss tanδ 0 0005 microwave quality factor q f 17 056 ghz.

A basic solution compatible with most ceramic and metal powders.

Excellent binder for producing high temperature protective coatings and refractory and chemically resistant adhesives and patching materials.

.jpg)